5 Steps to Harvesting for Quality and Compliance

Written by Ron Johnson on Apr 29, 2020

We know how much time and energy goes into getting your first legal harvest. Here’s a practical guide to ensure everything is done for quality and compliance!

1) Dark Period – Before cutting plants down giving plants 24 – 48 hours of dark has been known to improve potency and trichome structure. All the work you put in throughout the growth process is worth the extra time for a strong finish.

2) Deleaf or prune – Don’t go too crazy but remove 10-20% of the leaves. This will lower the workload on potential trimming staff once the plant is dry. The leaves left behind will contribute to a slower smoother drying process. Make sure to record the weight of the plant matter removed during this time.

3) Cut Whole Plants from Stock – Unless you’re harvesting massive plants in an outdoor environment it makes life easier to hang plants in one piece.

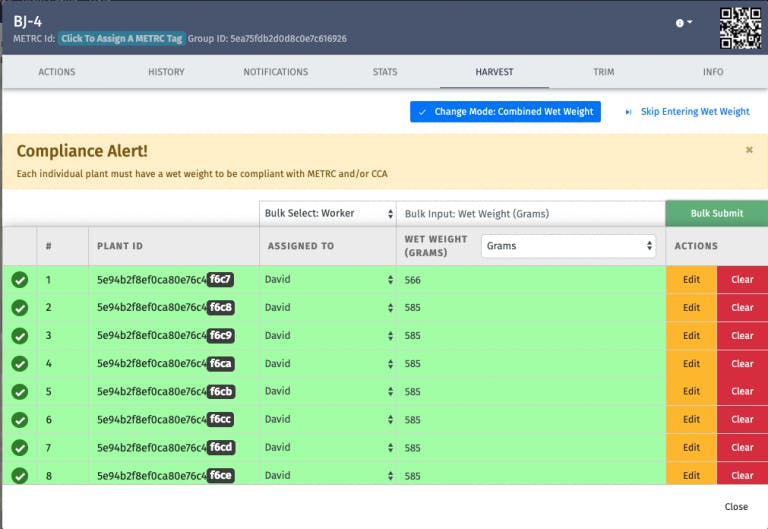

4) Recording Wet Weight (California Requirement but not for all states) – Remember how when you first planted immature plants and you used one tag per plant lot.That plant lot number is now relevant again.

- Immature(Seedling/Clone/Veg) – One Plant Lot ID for Plants

- Mature (Flowering) ID for each plant in lot

- Log wet weight for each id

- All wet weight accumulates unders original Plant Lot number

According to California Track and Trace regulations one must report the wet weight of each individual plant at the time of harvest.

Weighing each plant individually can be a long process especially when your facility has 100’s and even 1,000’s of plants in many scenarios.

Bulk harvest strategies for licensed accounts.

Average plant weight – Once you have your average plant weight per batch. Simply select the batch by scanning a tag or selecting the batch.

Image from GroLens web app harvesting window

Enter in the average weight once and it distributes that weight across the batch and you’re done!

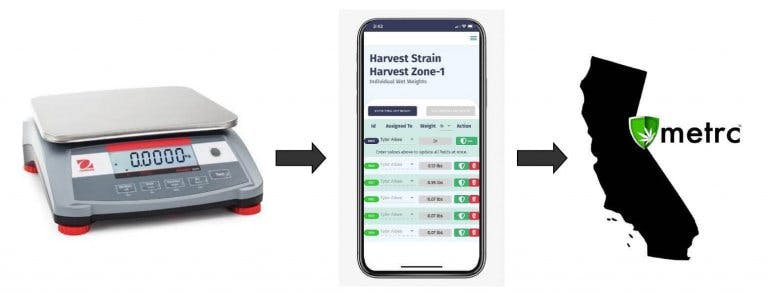

Scale Integration – One of the many great use cases for scale integration is when weighing individual plants.

Visualization of bluetooth scale integration for reporting to metrc. Scale used is an Ohaus Ranger 3000

After the proper setup with the GroLens mobile app you set the plant on the scale, click save, and the harvest weight we automatically populate in GroLens.

5) Drying – After doing any necessary harvest reporting you want to immediately hang your plants for drying.

A good dry room will be between 60-70 degrees and 50-60% humidity. It is also important not to pack plants too tight. Hanging lines at least 24-36 inches apart will give staff room to maneuver and the plants sufficient space to dry.

Marijuana hangs in the drying room at Harboside Farms in Salinas, Calif.

You want your plants to dry in 9-12 days. Drying the branches until they make a snapping noise is a good indicator of when your plants are ready to be trimmed.

Following these steps should put you on track to a successful harvest!